- Description

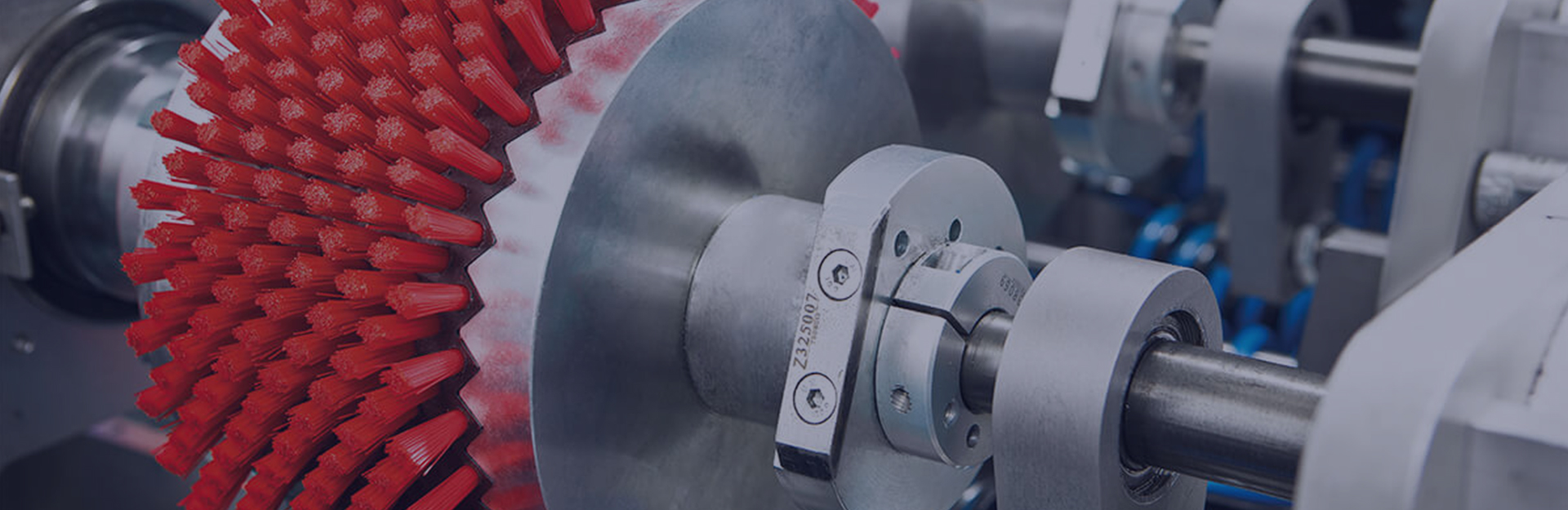

Disc brushes are classified by material: brush body is made of PP PA、POM、PS、ABS、 Aluminum and electric wood panels; The bristles are made of PP, nylon, abrasive fibers, sisal, pig hair, etc; There are generally four types of applications for disc brushes in industry, which can be summarized as one point: to achieve the desired finishing effect on the surface of the workpiece. So, the main task of the disc polishing brush is to process the surface of the workpiece. Let's take a closer look at the four types: satin decoration: satin decoration is the process of using a soft and fine polishing brush to brush the surface of the part into a diffuse reflection layer of matte satin, which can give the surface of the part a non mirror like sparkling luster. Surface cleaning: mainly uses a disc polishing brush to clean the oxide scale, rust, old paint layer, welding slag and other dirt on the surface of the parts. It is also used to brush away the residual floating ash after the parts are corroded. Silk pattern brushing: Use a disc polishing brush to brush certain regular and fine silk patterns on the surface of the part, such as wavy patterns, fish scale patterns, etc., to achieve decorative purposes.

Remove burrs: Remove burrs on the edges of machined parts by brushing. This is also a type of disc polishing brush that is widely used in industry.

EN

EN AR

AR ES

ES FR

FR VI

VI