Introduction to various types of bristles in brushes

Introduction to various types of bristles in brushes

- General characteristics of bristles

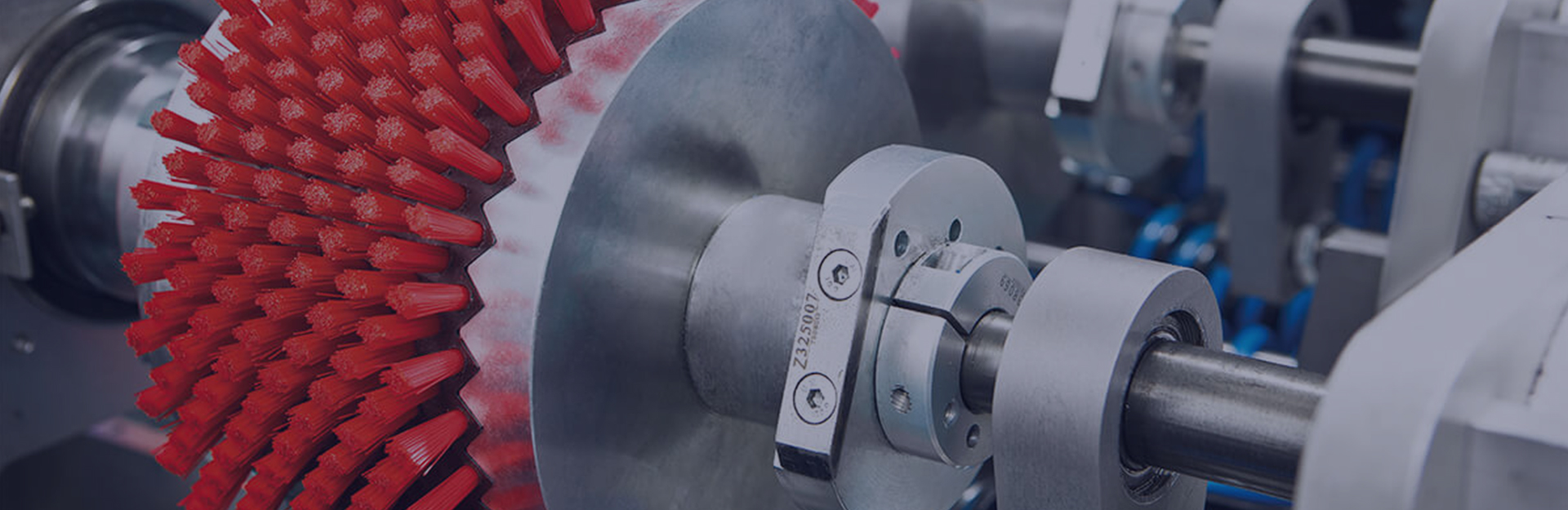

Synthetic bristles can be divided into two categories: one is curled, like waves, which we call wavy bristles; Another type of horizontal straight, we call it straight silk. For brushes of the same specification, fill them with roughly equal amounts of corrugated and straight filaments. The corrugated filaments are denser than the straight filaments, but there are gaps between them, which may result in residual debris; The straight wires are more tightly connected and are more suitable for sealing, dust prevention, etc. When selecting bristles, the length and diameter of the bristles will affect their stiffness.

- Brush color

The color of the bristles can be customized, but black, white, and natural colors are common. Natural color does not contain any color additives and looks a bit like white, but it is actually lighter than white and sometimes appears as light gray. If you need to use real white, we recommend using white instead of natural colors .

- Brush filling material

The filling materials for brushes are diverse, generally divided into synthetic plastic wire, animal hair, natural plant wire, and metal wire. Different materials of brush wire have different uses and functions. When choosing bristles, it is determined by the purpose of the brush.

Let's take a detailed look at the properties of bristles.

① Nylon thread

Polyamide, commonly known as Nylon or PA, has a density of 1.15g/cm3 and is a general term for thermoplastic resins containing repeating amide groups - [NHCO] - on the main chain of the molecule,

Nylon is commonly divided into three grades: nylon 6, nylon 66, and nylon 612.

They have the following characteristics: ① high softness, excellent elasticity memory, bending recovery force, and first-class homework ability; ② Excellent resistance to chemical reactions, dirt, and wear; ③ Capable of working at high temperatures and withstanding high-temperature disinfection; ④ Low water absorption rate; ⑤ There will be no surface peeling.

Among them, nylon 612 is a relatively high-quality nylon filament with low water absorption, better recovery and wear resistance than nylon 66. In addition, nylon 612 has anti mold and antibacterial properties, and its brush wheels, brush strips, etc. are often used in food, medical, and electronics related industries; Nylon also includes anti-static nylon and flame-retardant nylon.

Nylon bristles are widely used due to their excellent elasticity and flexibility. Among them, the bristles of PA610, PA6, and PA66 have excellent wear resistance and resilience, as well as high temperature resistance and acid and alkali resistance, making them very suitable for industrial brush components used in dust removal and cleaning, such as vacuum cleaner brush strips, road cleaning machine brush rollers, etc. The bristles of PA612 and PA1010 have better resilience, but their cost is relatively high and their wear resistance is slightly inferior. Therefore, they are more suitable for use as brush strips for back and forth cleaning of industrial equipment and dust-proof brushes at the bottom of doors and windows.

② Abrasive wire/wear-resistant wire

Abrasive wire is a synthetic wire made by adding silicon carbide (SIC) or aluminum oxide (AO) abrasive particles to nylon 6 or nylon 612 as the brush material. It is also known as abrasive wire or grinding wire in the industry. The brush products made from it have wear-resistant characteristics, and there are various types according to wire diameter and mesh size. It is commonly used in surface treatment of PCB, pickling line of galvanized sheet, metal processing, polishing and deburring.

③ Polypropylene (PP filament)

Polypropylene (PP for short) is a thermoplastic resin made by polymerizing propylene. The characteristic of PP is that its density is less than 1. When testing the wool material, several of them can be placed in water. If they float on the water surface, it can be preliminarily judged as PP material; The cross-section of PP wool is elliptical; In addition, PP has poor elasticity and is difficult to restore to its original state after multiple bends; Can withstand heat up to 120 degrees Celsius, suitable for industrial dust removal and cleaning of rough components, such as dust removal in mining docks, sweeping brushes in sanitation vehicles, and so on.

④ Natural plant fibers

White brown is a woolen material made by processing fibers from the stems and leaves of agave plants. It is mainly produced in Mexico and is therefore commonly referred to as "Mexican white brown" in the industry; White brown has good acid and alkali resistance; Due to its plant fiber nature, it has good water absorption; White brown can reach a temperature of around 140 degrees Celsius and is suitable for use as a brush for detailed polishing and polishing operations in leather manufacturing. In addition, there is also sisal, which is one of the natural materials used to process brushes. The performance of sisal is similar to that of white brown, and it is often used to process into polishing brushes. The finished product is commonly known as "sisal strips".

Sisal brush silk has good toughness, high temperature resistance, and oil absorption. It is commonly used for pot brushes or high-temperature, degreasing purposes.

⑤ Horse hair

The softness of horsehair is between that of pig's mane and wool, and horsehair is slightly harder than pig's mane; Horse hair has good toughness and wear resistance, but it is not resistant to acid and alkali. When made into brushes, they are often used in industries such as polishing, cleaning, and dust removal; Brushes made of horsehair can withstand high temperatures of around 190 degrees Celsius. Horse hair is softer than pig mane and easier to remove floating dust. It is often used in high-end household cleaning products or for industrial purposes such as removing floating dust.

⑥ Pig's mane

The common colors of pig bristles are brown (white) or black. Pig bristles have excellent durability and water resistance, as well as anti-static, high-temperature, and acid-base resistance. Pig bristles are commonly used for polishing bath brushes or precious objects, such as gold, gemstones, pianos, etc. They are also suitable for polishing and grinding hard alloys.

⑦ Wool

Wool is relatively soft and lacks elasticity. When made into a wool brush, it will not leave any brush marks when used to apply paint, and has excellent polishing and cleaning properties. It is non-conductive.

⑧ Metal wire

Metal brush wire alias (corrugated brush wire, truncated brush wire, straightening brush wire, etc.). The more common materials include stainless steel wire, copper wire, steel wire, galvanized steel wire, copper plated steel wire, copper-clad aluminum wire, etc. There are two types of metal wire processing methods: corrugated wire (the metal wire is corrugated and then cut); Cut off the wire (straighten the metal wire and then cut it off). Metal wire is generally used for deburring and other treatments on metal surfaces, and its wear resistance is good.

EN

EN AR

AR ES

ES FR

FR VI

VI