How to choose a photovoltaic solar cleaning machine roller brush

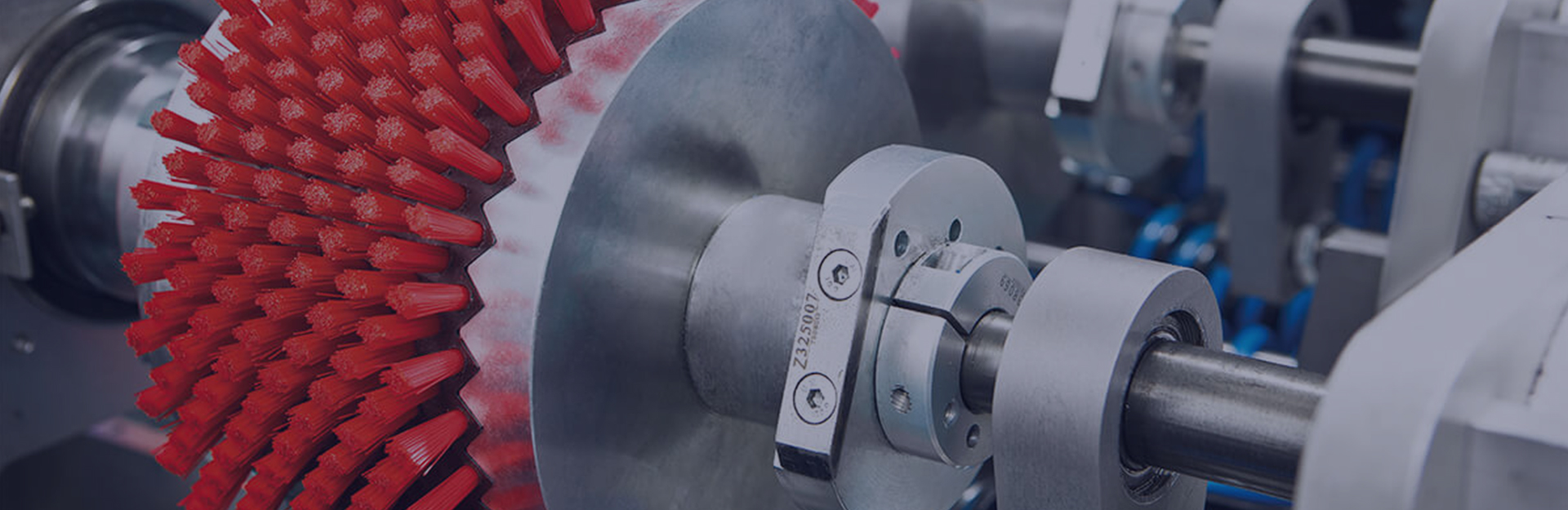

Photovoltaic solar cleaning machine is a specialized equipment used to clean photovoltaic panels, in which the rolling brush is an important part, which can remove various dirt and dust on the photovoltaic panels and improve the power generation efficiency of the photovoltaic panels.

However, there are various types of roller brushes on the market with different qualities. Choosing the appropriate roller brush is the key to using a photovoltaic solar cleaning machine. Below, we will provide a detailed introduction to the material, hardness, length, and diameter of the roller brush to help everyone better choose the roller brush.

Roller brush material

1.The material of the roller brush directly affects its service life and cleaning effect. Common roller brush materials include nylon, PP, PBT, etc.

2.Nylon material: Nylon material roller brush has a smooth surface, high hardness, and relatively long service life, suitable for cleaning dirt and dust on the surface of photovoltaic panels. Meanwhile, the nylon material roller brush has strong corrosion resistance and longer service life.

3.PP material: Compared with nylon material, PP material has relatively lower hardness and is mainly suitable for cleaning finer dirt and dust.

4.PBT material: PBT material has moderate hardness, strong adaptability, easy cleaning, and is less likely to deform after collision.

5.Overall, nylon material roller brushes have high hardness, good corrosion resistance, and long service life, making them suitable for routine cleaning work; The rolling hardness of PP material is relatively low, making it suitable for fine cleaning. PBT material has moderate hardness, good anti-corrosion performance, and a wide range of applications. Therefore, when choosing a roller brush, the appropriate material should be selected according to the actual scene.

Rolling brush hardness

Roller brush hardness refers to the hardness of the bristles of the roller brush. The commonly used hardness levels include soft, moderate, hard, and superhard, which are suitable for different cleaning tasks.

1.Soft bristle roller brush: Soft bristle roller brush is suitable for cleaning photovoltaic panels with relatively flat surfaces, which will not cause damage to the surface, but the cleaning effect will be limited to some extent. Material 0.2 nylon.

2.Moderate brush: Moderate brush has moderate hardness and is suitable for cleaning various types of photovoltaic panels, making it the mainstream choice in the market.

3.Hard brush: Hard brushes have high hardness and are suitable for cleaning stubborn stains, but may cause damage to the surface of photovoltaic panels.

4.Super hard brush: Super hard brushes are mainly used to clean surfaces of relatively hard objects, such as concrete or stones, and are generally not suitable for cleaning photovoltaic panels.

Therefore, the selection of roller brush hardness should be based on the actual situation, matched with the material and surface condition of the photovoltaic panel, to ensure cleaning effect and service life.

Roll brush length

The length of the roller brush is usually calculated in millimeters. Choose the appropriate length of roller brush according to the size and shape of the photovoltaic panel to ensure that every corner of the photovoltaic panel can be thoroughly cleaned.

1.Long roller brush: Long roller brush is suitable for cleaning large-area photovoltaic panels, which can quickly and efficiently clean the entire photovoltaic panel. However, for small and narrow photovoltaic panels, it may not achieve complete cleaning effect.

2.Short roller brush: Short roller brush is suitable for cleaning small areas of photovoltaic panels, easy to operate, and can clean to difficult to reach positions.

3.The length of the roller brush should be selected according to the specifications and cleaning needs of the photovoltaic panel. For example, for larger photovoltaic panels, it is recommended to use a long roller brush for cleaning, while for smaller photovoltaic panels, a short roller brush can achieve the cleaning effect.

Roller brush diameter

The diameter of the roller brush is usually calculated in millimeters, and the appropriate diameter of the roller brush is selected based on the size, material, and cleaning task of the photovoltaic panel to ensure the cleaning effect and speed.

1.Small diameter roller brush: Small diameter roller brush is suitable for cleaning photovoltaic panels with small cleaning areas and shallow closing. The cleaning effect is good, but the work efficiency is relatively low.

2.Large diameter roller brush: Large diameter roller brush is suitable for cleaning photovoltaic panels with large cleaning areas and deep closing, with high cleaning efficiency, but may cause certain damage to the surface.

Therefore, when selecting the diameter of the roller brush, the appropriate diameter should be chosen according to the actual situation to ensure the cleaning effect and work efficiency.

In short, choosing the appropriate roller brush is the key to using a photovoltaic solar cleaning machine. The selection should be based on the size, material, shape, cleaning requirements of the photovoltaic panel, as well as the material, hardness, length, and diameter of the roller brush. At the same time, in order to ensure the service life and cleaning effect of the roller brush, it should be regularly cleaned and maintained.

EN

EN AR

AR ES

ES FR

FR VI

VI