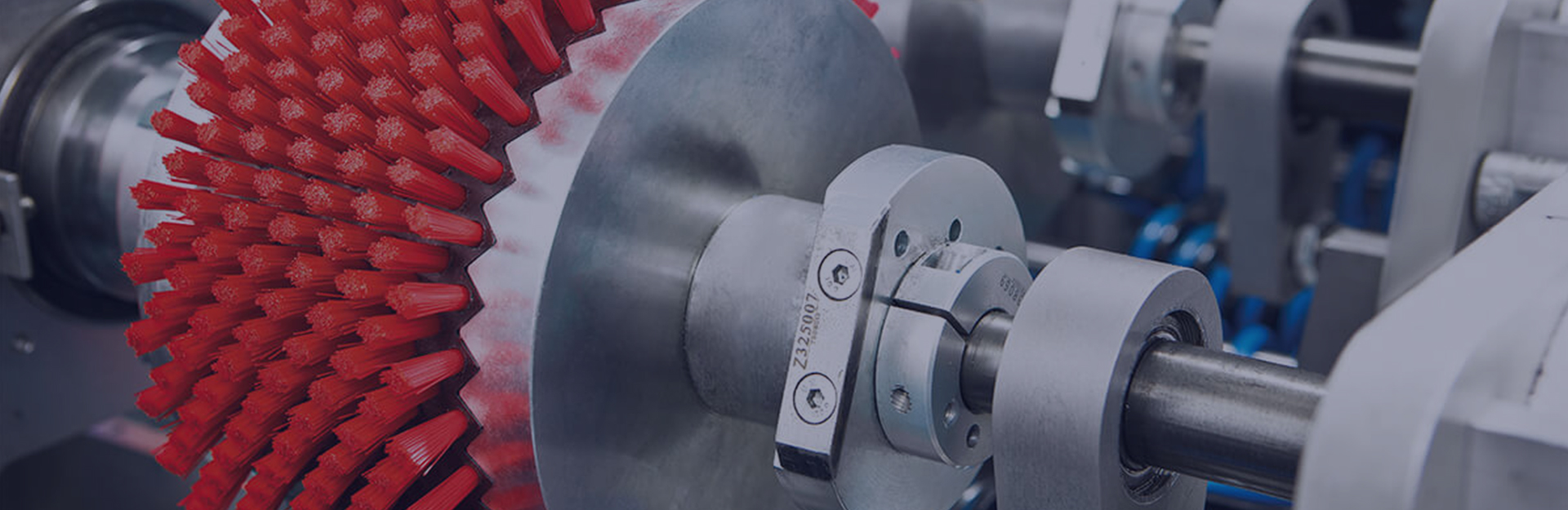

How is the brush roller used for polishing and cleaning?

A brush roller is a tool used for polishing and cleaning, usually made of materials such as steel wire, copper wire, nylon wire, etc. Brush rollers are widely used in various surface treatment fields, such as construction, automotive, machinery, home furnishings, shipping, and other industries. Let's take a look at the application and usage of brush rollers in polishing and cleaning:

Polishing and cleaning

Brush rollers can be used for electric and manual grinding, polishing, and cleaning, mainly for cleaning and removing surface oxides, rust, and dirt on raised areas, edges, and small areas around components. These processes can make the surface of sheet metal, plastic, or wood smooth and shiny, obtain clear markings, and improve product quality.

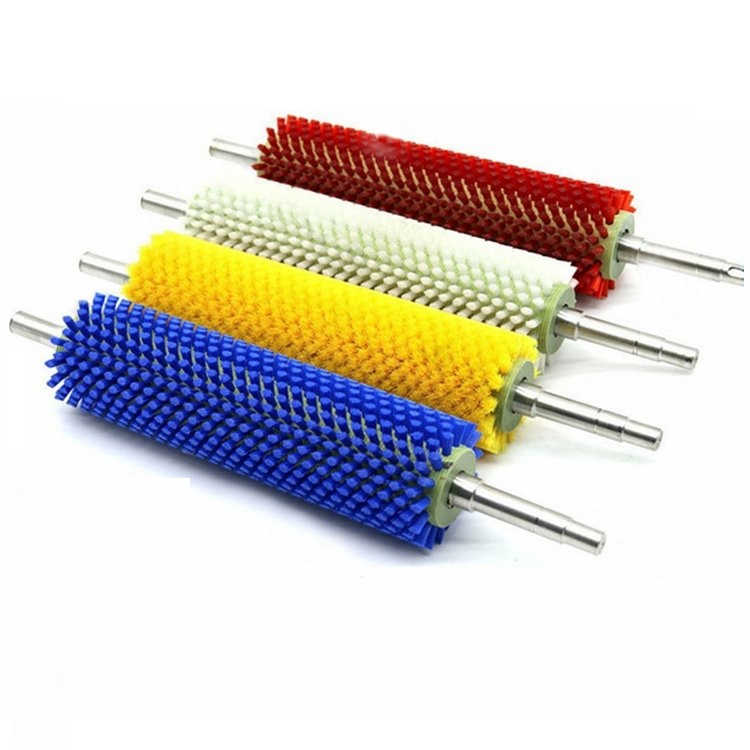

Choose an appropriate brush roller

It is crucial to select the appropriate brush roller based on the surface type and shape that needs to be treated. For example, for harder surfaces, a wire brush roller should be selected; For more fragile surfaces, choose a soft nylon wire brush roller. At the same time, when performing surface polishing, the use of abrasives with different particle sizes and materials should also be considered.

Preparation work

Before using a brush roller for polishing and cleaning, the surface to be treated needs to be cleaned thoroughly to ensure it is spotless. At the same time, safety devices, suitable gloves, and efficient lubricants should be prepared to enhance operational control.

Usage method

1.Choose the appropriate brush roller according to the needs, clamp the brush roller on the drill head or manual flywheel.

2.Spray the lubricant evenly on the surface that needs to be treated. This can ensure smooth operation of the brush roller and also prevent local damage to the riveting area.

3.Place the brush roller on the surface that needs to be cleaned, gradually increase the operating force, and perform uniform and standard polishing and cleaning along the direction to be polished until the desired surface is smooth, free of rust spots, oxides, and other dirt.

4.Due to the possibility of generating a large amount of dust and debris after surface treatment, it should be cleaned in a timely manner even before being transferred to different positions. After processing, it is necessary to re-examine whether the surface is flat and smooth to ensure effective improvement in quality.

Precautions

1. When operating, be sure to pay attention to safety and avoid injury.

Before selecting the appropriate brush roller, it is necessary to carefully inspect the type and shape of the surface being treated to avoid damage or contamination.

EN

EN AR

AR ES

ES FR

FR VI

VI